December 1, 2025 | 13:06 GMT +7

December 1, 2025 | 13:06 GMT +7

Hotline: 0913.378.918

December 1, 2025 | 13:06 GMT +7

Hotline: 0913.378.918

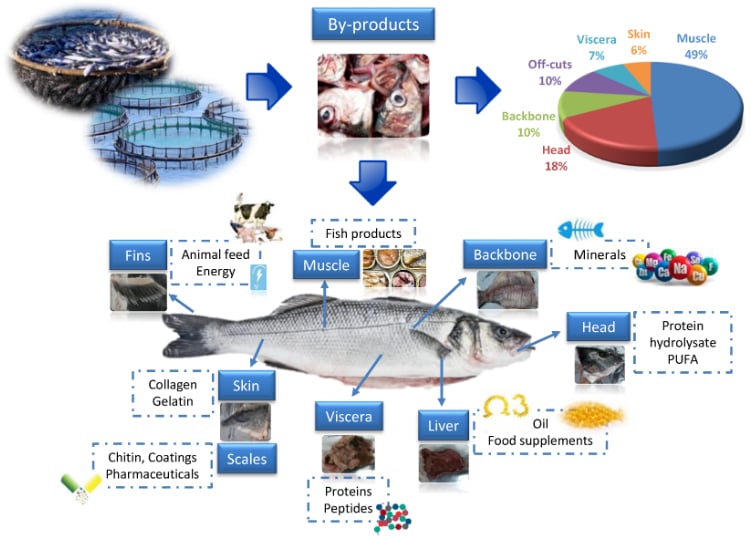

In the global seafood production chain, 60-70% of the biomass is discarded as by-products such as heads, bones, skin, and internal organs. According to the Food and Agriculture Organization of the United Nations (FAO, 2022), over 70 million tons of by-products are wasted annually, but most have not been fully utilized to their potential.

Amid a global shift toward green growth and a circular economy, by-products are increasingly viewed as valuable secondary resources that reduce environmental pressure and enhance the value of the production chain.

According to the Directorate of Fisheries (2024), Vietnam’s pangasius, shrimp, tuna processing industries generate about 1.3 million tons of by-products each year, but only around 30% are currently utilized, mainly for low-value fishmeal. The remainder, if not properly treated, causes waste and pollution.

Shrimp heads and shells containing chitosan are raw materials for the pharmaceutical industry. Illustration photo.

Meanwhile, by-products contain many high-value components used in healthcare, functional foods, cosmetics, and industry. Fish skin and bones can be extracted for collagen and gelatin; shrimp shells produce chitosan and astaxanthin; fish heads and livers are rich sources of omega-3.

According to SINTEF (Norway, 2024), fully utilizing these by-products could increase the value of the production chain by 30-60%.

Many countries have transformed seafood by-products into a high-value auxiliary economic sector. Norway utilizes 92% of by-products for biomedical and nutritional products. Iceland pursues a “zero waste” seafood model. Japan extracts enzymes from tuna organs for use in seasonings and pharmaceuticals. India has dozens of startups developing products from shrimp and crab by-products.

In Europe, BioMarine has successfully commercialized hydrolyzed protein from cod, exporting to 40 countries with annual revenue exceeding 150 million USD.

In Vietnam, pioneering companies like Vinh Hoan Corp have produced collagen from pangasius skin, earning over 600 billion VND in 2023. Sao Mai Group exports premium fish oil and fishmeal to Japan and South Korea. NTSF Seafoods develops biodegradable films from shrimp shells - a promising alternative to plastic.

However, many businesses have yet to deeply engage in this sector due to lack of capital, technology, and supportive policies. Additionally, by-products are highly perishable and require processing technologies such as enzymatic hydrolysis, membrane filtration, and ultrasound - technologies not widely available in many processing plants today.

The government has issued numerous policies to promote sustainable development of the seafood industry. Notably, Prime Ministerial Decision No. 1408/QD-TTg dated August 16, 2021, approved the project on developing the seafood processing sector for the 2021–2030 period. The plan aims to increase the added value ratio of processed seafood products to 40%, with a focus on utilizing by-products to produce high-value products such as collagen, gelatin, fish oil, and chitosan.

Fish processing by-products include heads, tails, bones, fins, scales, belly fat, intestines, internal organs, and meat scraps. Illustration photo.

Not only from the government side, many experts also encourage investment in modern technology and leveraging supportive policies. Mr. Tran Dinh Luan, Director General of the Directorate of Fisheries, emphasized the need to promote public-private partnership models, connecting businesses with research institutes and universities to apply new technologies in by-product processing.

Another important approach is building a sustainable supply chain for by-products, from collection and preservation to efficient transportation. The entire chain operates in coordination, from processing plants to facilities producing high-value products.

Fish processing not only produces main products but also utilizes by-products for high-value products serving the pharmaceutical, functional food, and cosmetics industries. Illustration photo.

By-product industries are emerging as a solution to the circular economy challenge. Developing this sector not only helps businesses increase profits but also brings social and environmental benefits.

First, it reduces dependence on imported raw materials in the food, pharmaceutical, and cosmetic industries. Second, deeply processed by-products can be exported at high value, diversifying the product portfolio. Third, efficient use of by-products means lower carbon emissions, better organic waste management, and contribution to the Net Zero 2050 goal.

Moreover, the by-product industry can create numerous jobs in farming areas and processing plants, where unskilled labor is prevalent.

According to the Ocean Panel report (2023), effective exploitation of by-product resources could boost the ASEAN blue economy GDP by 1.5–2% by 2030.

Seafood by-products are no longer forgotten leftovers. With a well-planned strategy, from infrastructure and technology to supportive policies, Vietnam can turn discarded materials into a new growth driver. It is time to reconsider: in the value chain, nothing is meaningless if exploited at the right time and in the right way..

$ 1 = VND 25.810 - Source: Vietcombank.

Translated by Phuong Linh

/2025/11/28/3433-1-212821_213.jpg)

(VAN) Many localities across the coconut land of Vinh Long are replicating emission-reducing models in production and daily life, contributing to the targets for emission reduction and green economic development.

(VAN) The green transition is an inevitable path for collective economy to achieve balanced growth and align with global trends.

(VAN) The TH Group is not only Vietnam’s leading clean-milk producer; it is also leaving a strong mark on sustainable development as it pursues the goal of carbon neutrality.

/2025/11/27/3830-1-152901_403.jpg)

(VAN) Dong Nai is developing its key crop areas, expanding planting area codes, and applying high technology to increase the value of agricultural products, aiming at a green and sustainable agriculture.

(VAN) Tay Ninh’s livestock sector is undergoing a major transformation, applying high-tech, closed-loop circular models to build sustainable value chains.

/2025/11/26/3627-4-082628_818.jpg)

(VAN) From a small café on the red basalt highlands, Le Van Hoang started a business with clean coffee, building Enjoi Coffee into a symbol of organic agriculture in the Lam Dong plateau.

/2025/11/25/0045-1-135246_13.jpg)

(VAN) Ca Mau is researching a model of sea-encroaching embankments combined with viaducts and logistics service zones, aiming both to prevent erosion and create land funds for marine economic development.