November 25, 2025 | 13:54 GMT +7

November 25, 2025 | 13:54 GMT +7

Hotline: 0913.378.918

November 25, 2025 | 13:54 GMT +7

Hotline: 0913.378.918

Ajinomoto Vietnam has been actively reducing fossil fuel use, cutting down on electricity consumption, and promoting the use of renewable energy sources. Photo: Tuoi tre online.

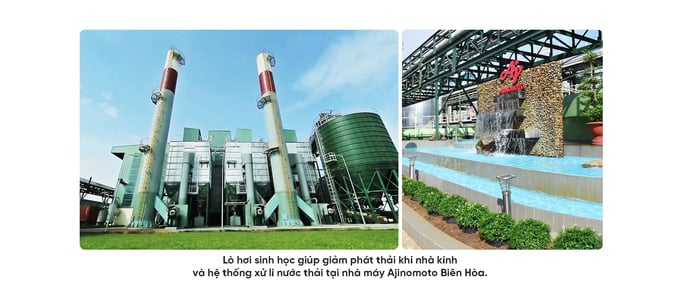

During the "Understanding Ajinomoto Vietnam's Efforts in Contributing to the Health and Happiness of Vietnamese People and Society" program, company representative Hoang Van Quoc Chuong stated that since 2014, the company has been operating biomass boilers using compressed rice husk as fuel instead of oil/gas to generate steam for production, resulting in a 48% reduction in greenhouse gas emissions.

“Recognizing this, rice milling plants in the Mekong Delta have invested in pelletizing systems to supply companies using rice husk as fuel. This has led to the formation of a rice husk pellet production market in Vietnam and presents potential for exporting rice husk as fuel to international markets in the future”, Mr Chuong affirmed.

Ajinomoto Vietnam also announced plans to study and implement a solar power system at the Ajinomoto Long Thanh Factory, covering an area of 16,000 m² with a capacity of 2,000 KW.

In addition, reducing plastic waste is a key focus for Ajinomoto Vietnam in its environmental protection and corporate social responsibility efforts. Notably, in early 2024, with the goal of promoting packaging collection and recycling, minimizing plastic waste, and establishing a circular economy model in waste management under the Extended Producer Responsibility (EPR) program, Ajinomoto Vietnam signed cooperation agreements with entities on the list of product and packaging recyclers published by the Ministry of Natural Resources and Environment, who have been granted environmental permits as per legal regulations.

At the Ajinomoto factory, waste is sorted to implement effective recycling methods.

Tetsuya Osawa, Deputy General Director of Ajinomoto Vietnam, emphasized, "The Ajinomoto Group has declared its goal of achieving net-zero emissions by 2050. The strategy for Scope 1 and 2 involves implementing cogeneration systems and investing in greenhouse gas emission reductions, including the purchase of non-fossil certificates. For Scope 3, we are enhancing cooperation with partners, including suppliers, and developing and applying new technologies. The goal for Scope 1 and 2 is to reduce greenhouse gas emissions by 50% by 2030, while the goal for Scope 3 is to reduce emissions by 30% by 2030 (compared to 2018)."

To minimize the extraction of natural water for production purposes, Ajinomoto Vietnam has invested in and put into operation a cooling tower system and a dedicated water reservoir within the factory premises to recycle water for cooling machinery. Additionally, for wastewater from production activities, the company has invested over VND 100 billion in a wastewater treatment system, applying modern biological treatment technology to handle wastewater generated from daily production and living activities.

The company has also implemented a series of activities to reduce food loss and waste during production, from receiving raw materials to distributing products to customers. This includes improving production processes, optimizing delivery times, and establishing management systems to ensure the efficient use of production materials... Furthermore, the company contributes to reducing food loss by utilizing surplus materials from the production process to create fertilizers and animal feed ingredients for agriculture.

Currently, Ajinomoto Vietnam has achieved its goal of recycling 100% of food waste and has eliminated food loss.

Translated by Hoang Duy

(VAN) With its diverse ecosystem, Phu Quoc National Park plays a vital role in environmental protection and biodiversity conservation and serves as the core zone of the Kien Giang World Biosphere Reserve.

(VAN) Cooperation activities under the Aus4Skills program focus on: logistics professional development, competency-based training and assessment (CBTA), leadership innovation, and digitalization.

(VAN) Minister Tran Duc Thang has affirmed that the models developed by Que Lam Group serve as a practical foundation for the Ministry of Agriculture and Environment to direct wide-scale replication.

(VAN) Viettel is applying automation technology that helps Vietnamese agro-products clear customs more quickly, cut costs, and maintain quality.

(VAN) Vinh Long, Viet Nam’s ‘coconut capital,’ is facing a major opportunity to advance sustainable agriculture by reducing carbon emissions from cultivation.

(VAN) Ho Chi Minh City still has many areas for improving forest quality, saving energy, reducing emissions, and generating carbon credits.

(VAN) ILDEX Vietnam 2026 will connect more than 250 exhibitors and 10,000 visitors from 40 countries.