December 5, 2025 | 01:56 GMT +7

December 5, 2025 | 01:56 GMT +7

Hotline: 0913.378.918

December 5, 2025 | 01:56 GMT +7

Hotline: 0913.378.918

Biochar is produced by heating biomass, such as rice straw, corn cobs, coffee husks, cashew shells, and tree branches at high temperatures in a low- or no-oxygen environment. The result is a carbon-rich, stable form of charcoal that is resistant to microbial decomposition, capable of retaining water and nutrients, and known to improve soil structure.

What makes biochar unique is its ability to lock in a large portion of the carbon originally stored in the biomass. Instead of being released into the atmosphere as black smoke, like in traditional open burning, the carbon becomes sequestered in the durable structure of the charcoal. When applied to soil, biochar can store carbon for hundreds or even thousands of years.

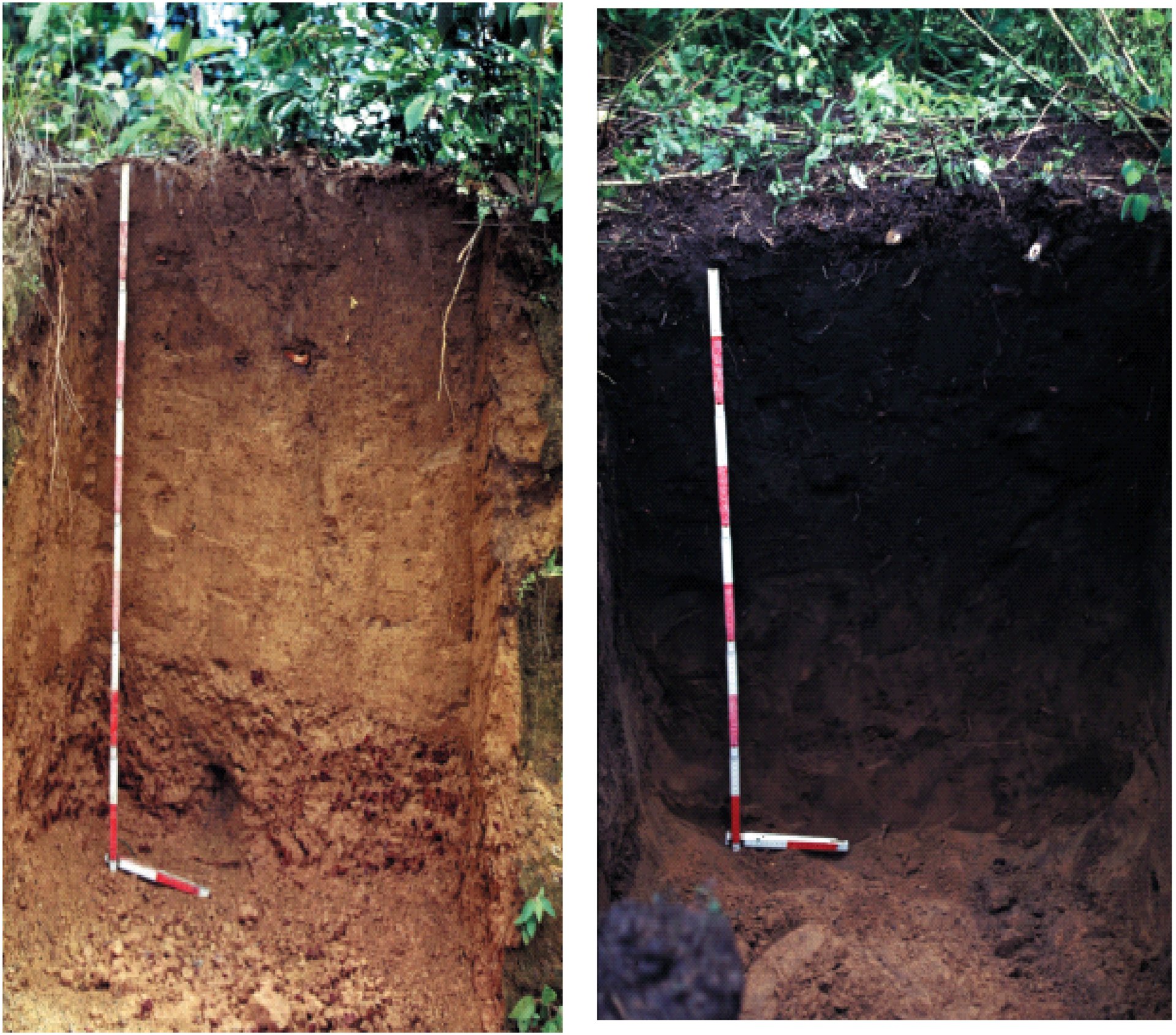

When incorporated into soil, biochar can store CO2 and enhance soil fertility. In the photo: regular soil (left) and soil enriched with biochar (right). Photo: Allpowerlabs.

According to international studies, each ton of biochar can sequester an average of 2.2 to 3 tons of CO2 equivalent (CO2e), depending on the type of biomass and the production process. On the global voluntary carbon market, carbon credits derived from biochar are considered “high-quality carbon” due to their sustainability and co-benefits for both the environment and local communities. Among these benefits are improved soil conditions and enhanced plant growth, which in turn help capture even more CO2. While nature takes thousands of years to form 2.5 cm of topsoil, biochar can achieve similar results in just a few years.

In Southeast Asia, a bamboo-based biochar project in Chiang Mai, Thailand, is already generating and selling carbon credits. The model, supported by HelpAge International (HAI), aims primarily to provide elderly people with a stable source of income. This is a closed-loop cycle: bamboo is planted, shoots are harvested, bamboo residues are pyrolyzed into biochar, and the biochar is returned to the soil to nourish the bamboo, improving growth and increasing shoot yields.

Mr. Tran Ngoc Quyen, an expert from HAI's global office, shared: “When we guided local residents in the production process, people in Thailand quickly recognized the value of this ‘black gold’. Unlike chemical fertilizers, which must be reapplied every 3-4 months, compost made from biochar has no expiration date. It effectively improves soil health, maintains fertility, and reduces dependence on synthetic fertilizers. With sufficient water and nutrients, bamboo shoots can be harvested year-round. Particularly during the dry season, when shoots are scarce, their market price can be 2 to 4 times higher.”

The investment cost for large-scale biochar production equipment is approximately USD 1,000 (equivalent to VND 25 million), capable of producing 3-4 tons of biochar per day, or about 1,000-1,500 tons annually. Photo: HAI.

In terms of data, to verify carbon sequestration effectiveness, Thai farmers conduct regular measurements: with 1,600 bamboo clumps per hectare, they can yield approximately 268 tons of bamboo annually. After pyrolysis, this volume produces about 60 tons of biochar, which can retain around 54 tons of CO2.

In this model, a non-governmental organization acts as an intermediary between local communities and investors. It provides technical training on bamboo cultivation and care, biochar production, and methodologies for measurement and verification of emission reductions. The carbon credits are purchased by domestic companies seeking to offset their emissions or enhance their green and sustainable branding, thereby improving their market competitiveness.

In Chiang Mai (Thailand), the carbon credit price generated from this model reaches approximately USD 150 per ton of CO2 - equivalent to USD 29,600 per hectare per year (roughly 740 million VND).

Drawing from the experiences in Thailand and other international projects, HelpAge International (HAI) Vietnam is supporting the elderly community in Cao Son commune, Hoa Binh province to implement a bamboo planting and biochar production model. The core participants are members of the Intergenerational Self-Help Clubs (ISHCs) in Cao Son commune.

In the initial phase, local residents produced biochar from readily available materials such as firewood trimmings, bamboo scraps, and twigs. They composted the biochar with manure and applied it to home gardens. Within just 2-3 months, crops showed noticeably improved growth, inspiring broader adoption of the model across the community.

According to Ms. Tran Bich Thuy, Country Director of HAI Vietnam, the techniques introduced in Cao Son are widely practiced around the world. HAI has developed a simplified biochar-making methodology that is easy to learn and apply, requires low investment, and does not depend on complex infrastructure. In fact, villagers can simply dig a pit or repurpose used metal barrels to begin production.

Mr. Pham Xuan Dung, 68 years old, Chairman of the Elderly Association in Cao Son commune (Hoa Binh province), shared that biochar has brought about clear improvements in soil quality and has gained strong support from the local community. Photo: TN.

On the other hand, scaling up to an industrial level is not difficult. An investment of approximately VND 25 million (about USD 1,000) can support the production of 3-4 tons of biochar per day, equivalent to 1,000-1,500 tons annually. The project design is fully suited to the physical capacity of the elderly and is easy to implement in economically disadvantaged rural areas or any location with suitable conditions.

In fact, Vietnam has a rich and diverse supply of raw materials for biochar production. Agricultural by-products such as peanut shells, sugarcane bagasse, rice husks, coconut husks, cocoa shells, bamboo, and reeds are widely available but largely underutilized or used for low-value purposes. According to Mr. Quyen, the first step should be to develop a domestic biochar production model with reliable measurement methods and aim to sell carbon credits to local businesses. Once companies recognize the investment value, the market will develop on its own. At the same time, communication and training should be strengthened so that communities and local officials fully understand the benefits of biochar, from soil improvement and higher productivity to new income opportunities through carbon credits.

Ms. Do Thi Hong Dung, Head of the Department of Science and International Cooperation at the Institute of Agricultural Environment, noted that most biochar production models in Vietnam are still at the household level, with very few industrial-scale operations due to limited market demand.

Carbon credit trading represents a new and economically promising approach to green development and the goal of achieving net-zero emissions. However, the key challenge is how to demonstrate verifiable emission reductions and obtain certification and issuance of carbon credits that meet trading standards. This will require strong support from relevant stakeholders, particularly regulatory agencies, in establishing a legal framework, along with necessary incentive mechanisms and support policies.

Vietnam’s domestic carbon market is expected to be officially launched in 2028. With abundant raw materials, carbon credits from biochar could become a key export product for Vietnam and contribute significantly to the agriculture sector’s emission reduction goals.

Translated by Kieu Chi

/2025/12/01/2936-2-222331_70.jpg)

(VAN) Mortgaging his house and giving up a pharmaceutical management career, Mr. Nguyen Quang Duy succeeded in bringing Khanh Hoa's sea grapes to demanding markets such as Japan and the U.S.

(VAN) The large-scale agroforestry investment project aims to develop a leading sustainable agro-industrial center in Angola.

/2025/11/28/3433-1-212821_213.jpg)

(VAN) Many localities across the coconut land of Vinh Long are replicating emission-reducing models in production and daily life, contributing to the targets for emission reduction and green economic development.

(VAN) The green transition is an inevitable path for collective economy to achieve balanced growth and align with global trends.

(VAN) The TH Group is not only Vietnam’s leading clean-milk producer; it is also leaving a strong mark on sustainable development as it pursues the goal of carbon neutrality.

/2025/11/27/3830-1-152901_403.jpg)

(VAN) Dong Nai is developing its key crop areas, expanding planting area codes, and applying high technology to increase the value of agricultural products, aiming at a green and sustainable agriculture.

(VAN) Tay Ninh’s livestock sector is undergoing a major transformation, applying high-tech, closed-loop circular models to build sustainable value chains.